As a window tint installer, it is really annoying to see a window of vehicle with films looking purple, or the color that’s fading badly. And it is one the main concerns of end-users when selecting a car film for their drive.

The purple tint that develops on some window films over time is typically caused by a phenomenon called dye fading. This occurs when the dyes used in the window film degrade or break down due to exposure to UV radiation from sunlight. As the dyes deteriorate, they may shift in color, resulting in a purple or bluish hue.

Films that look purple are mostly dyed films. Dyed window film is a type of window film that contains a layer of dye laminated between layers of polyester film. The dye absorbs solar energy, primarily visible light, and helps to reduce glare and heat transmission through the windows. Dyed window film is known for its ability to enhance the appearance of windows by adding color and reducing glare, making it a popular choice for residential and commercial applications. It is usually it a very inexpensive entry level film. It comes in different thickness, 1mil, 1.2mil, 1.5mil.

However, dyed window film is less effective at blocking heat compared to other types of window film, such as ceramic films. It primarily works by absorbing solar energy rather than reflecting it away from the window. As a result, dyed window film may not provide as much heat rejection as other types of window film, especially in hot climates or areas with intense sunlight. Despite its limitations in heat rejection, dyed window film remains a cost-effective option for those seeking to improve the aesthetics of their windows and reduce glare with a tight budget. It is available in various colors and shades to suit different preferences and design requirements.

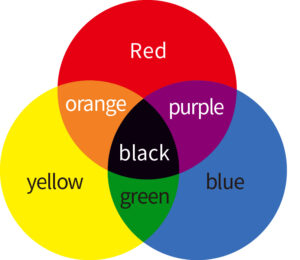

To make a dyed film black color shade, there are 3 primary colors are used -red, blue and yellow. Every color in the spectrum comes from a combination of these three colors. A complete absence of any primary color will give you absolute white, and a combination of equal parts all three primary colors will give you absolute black. As you can see in the picture, purple is a combination of the red and blue primary colors.

Primary-colored dyed

The window film you use, whether it is smoke, charcoal, neutral, or anything else, has the color derived from a mixture of these three primary-colored dyes. While all three of the primary colors are susceptible to fading from the sun, yellow typically fades at a faster rate than blue or red. As the film is exposed to sun and the yellow dyes fade out at a faster rate than the other primary colors, the mixture of the colors becomes primarily red and blue. As this occurs, the film begins looking purple—a color you would expect from a mixture of primarily red and blue dyes.

It is important to note that ALL dyed window films will fade over time. While films have warranties against color change and fading, there is simply no way to stop the fading process in a dyed film completely. Now that we understand what changes a film to appear purple, let’s look at some manufacturing processes that can slow down or address the effects of this fading.

First, the use of UV absorbers in the construction of the film can give dyed film a longer color life-span. UV absorbers will absorb the damaging UV rays and dissipate them in the form of heat. UV absorbers can be added to the adhesive layer, the core polyester film or a combination of both. The higher the quality and concentration of UV absorbers used in a film, the more protection those dyes have against the UV exposure. The more protection the dyes have against the UV exposure, the better the resistance to fading and color change the film will have.

The second thing that can be done to offset the effects of this fading is for the manufacturer to specify a particular mix of dyes designed to fade uniformly so that the film will “fade on color.” In order to keep a film from turning purple, you need to keep the yellow dye from fading out faster than the red and blue. So, care is taken to select a set of red, blue and yellow dyes that are matched for susceptibility to fading so that they will all fade at the same rate.

While the film will still fade over time, it will still retain its original color. So, your 35-percent film may look like a 45-percent film after a period of time, but it will still retain the original film color instead of turning purple. You can often see the effects of this when you look at older film that has a top edge that went inside the window frame or was protected by a sun visor. The portion of the film that was protected by the window frame or the visor retains the original darkness, while the exposed film has faded to a lighter shade of the same color.

To minimize the risk of window films turning purple, it’s essential to choose high-quality films with UV-stable dyes and to follow proper maintenance and care guidelines. Additionally, installing window films in areas with less direct sunlight exposure or using protective measures such as UV-blocking window treatments can help prolong the life of the film and prevent color shifting.

Ceramic window films are designed to resist fading due to their unique composition and properties. Here’s why ceramic film does not fade:

XO70-XO Nano Ceramic Window Tint Film SF18-SF Nano Ceramic Window Tint Film IR3090-IR Nano Ceramic Window Tint Film

- Advanced inorganic Nano Material Composition: Ceramic window films contain ceramic nanoparticles embedded within multiple layers of polyester film. These ceramic particles are highly stable and resistant to degradation from environmental factors such as UV radiation, heat, and moisture. Unlike traditional window films that rely on dyes or pigments to achieve color, ceramic films maintain their color and appearance over time due to the inherent stability of ceramic materials.

- UV Protection: Ceramic window films provide excellent UV protection by blocking out harmful ultraviolet rays. UV radiation is a major contributor to fading, discoloration, and degradation of interior surfaces such as upholstery, flooring, and furniture. By blocking UV rays, ceramic films help preserve the color and integrity of interior surfaces, reducing the risk of fading.

- Heat Rejection: In addition to UV protection, ceramic window films also offer superior heat rejection properties. They block a significant portion of infrared (IR) radiation while allowing visible light to pass through. By reducing heat buildup inside vehicles and buildings, ceramic films help mitigate the effects of thermal degradation, which can contribute to fading and discoloration over time.

- Color Stability: Ceramic nanoparticles used in window films are chemically stable and do not degrade or change color when exposed to sunlight or environmental conditions. This ensures long-term color stability and prevents fading, even in harsh climates or high-exposure areas.

- Quality Manufacturing: Ceramic window films are manufactured using high-quality materials and advanced production techniques to ensure consistency, durability, and performance. Manufacturers adhere to strict quality control standards throughout the manufacturing process to produce films that resist fading and maintain their optical properties over time.

KSB Nano Ceramic Films applies fine processed Tinx and Tungsten Oxide and heat rejection agent material to achieve a combination of high clarity and heat rejecting features. If you are looking for window films that does not fade over time and has a high heat rejection performance for your drive, ceramic films are your first choice.