PPF is known as paint projection film, or clear bra. It is in high demand with more and more car owners becoming aware the functionality of PPF to protect the appurtenance of their drive.

As consumers’ requirements are getting higher and higher, technology has also entered a stage of continuous upgrading, from the simple car washing, waxing, ceramic coating and so on. Now PPF is constantly in high demand today,because of its advantages of longevity. strong self-repair ability, and it can prevent scratches and isolate minor external pollution. Perhaps consumers will be more or less concerned that the PPF will turn yellow, fade or leave glue that stick to the original car paint. For this reason, it is particularly important to choose a High-quality and reliable PPF product.

As car owners, we all want to keep our vehicles looking brand new for as long as possible. One way to achieve this is by applying a protective film to the car’s paint. This film acts as a barrier between the car’s paint and external elements such as dirt, debris, and harsh weather conditions. But with so many options available in the market, how do we choose the best one?

Here’s what you need to know to choose a quality auto paint protection film.

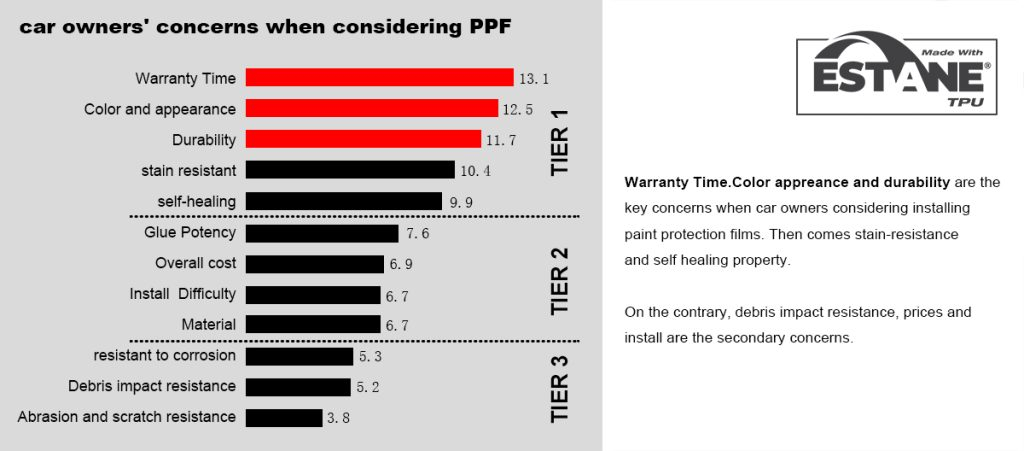

key concerns when thinking about putting on a PPF

Material matters

We know among all the paint protection film materials- PVC, TPH and TPU, that TPU is the best with durability and longevity. Well-known chemical giants like Lubrizol, BASF, Bayer, and Convestro takes up majority share of the world paint protection film Masterbatch supply. Renowned aftermarket auto care brands such as Xpel, 3M and Llumar also use those materials but with their own secret sources.

High-quality Lubrizol aliphatic substrate TPU is generally thought as one of the best, it has excellent ductility and tensile strength Made with Lubrizol ESTANE® TPU are sure for the assurance of consistent, reliable performance and ultimate peace of mind for your PPF products. with more than 30 years’ proven experience in Paint Protection Film (PPF) products, ESTANE® TPU from Lubrizol Engineered Polymers has earned its credibility and reputation as the PPF industry’s preferred thermoplastic polyurethane (TPU) polymer technology. When you choose PPF made with Lubrizol’s ESTANE® TPU you get more than just an ingredient. You get access to decades of material science and analytical expertise as an invaluable extension of your team.

Our premium PPF products are made with Lubrizol TPU material to ensure the long longevity and no yellowing, cracking or peeling off of the paint protection film.

The thickness of the paint protection film varies from 6.5mil to 10 mil, but it does not mean the thicker is better, we need to consider the workability of those films. The most regular film is 7.5 mil, they proved to offer the best projection in combine with duality and stability.

The thickness of the protective film is an important factor. Films that are too thin cannot withstand the harsh weather test, while the too thick ones are too hard to work with. From most of the paint protection installer’s feedback-that 7.5 mil PPF offers better protection against scratches, dings, and other minor damages. A high-quality film should be at least 6.5 mils thick to provide adequate protection.

Clarity Is Key

One of the biggest advantages of using an invisible car paint protection film is that it is virtually invisible. This means that the clarity of the film is critical. The film should be clear and transparent, without any haziness or cloudiness that could distort the car’s paint. A high quality paint protection film should stand the weather test in years and does not turn yellow, crack, delaminate or become haze. Paint protection film made with Lubrizol’s ESTANE® TPU are tested and proved by market and end user for years. It is one of the most trusted materials for PPF.

Self-healing-the Nano-level injected double coating

Quality PPF has a strong self-healing coating, which is more adaptable to the daily environment, durable and resistant to yellowing. This coating adopts a new generation of hydrophilic, antifouling and self-repairing coating combined with nano-density anti-leakage coating functions

① Wetting the surface with hydrophilic property can remove the oil, dust and dirt attached to the surface under the scouring of water;

② The dense coating has super impermeability, completely eliminating the penetration of rain spots, matting and oil stains;

③ With scratch memory function

Any minor scratches and scratches can be repaired by themselves at a certain temperature. This nano coating can help retaining the fine beaty of your beloved drive vehicle’s paint finish. The self-repair or self-healing coating can also provide a stain resistance property, while the soft grade beneath absorbs impact from stone and road debris.

High-quality films have self-healing properties. This means that the film can repair minor scratches and scuffs on its own, making it an ideal choice for car owners who want to maintain their car’s flawless appearance.

Premium quality glue

Another factor to consider is the ease of installation. A quality film should be easy to install and should not require special tools or expertise. It should also be removable without leaving any residue or damage to the car’s paint.

To perfectly install a PPF to a vehicle and have it stay in good shape for years, a reliable glue to bond the material to the paint surface is essential. We have Ashland high molecular, low initial potent adhesive glue to achieve a golden combination of cohesive strength and durable adhesion. There are trial and error when installing the PPF to edges and corners here and there, a low initial bonding glue will help the install process much easier. But once it is installed properly the potency of the glue will ensure a tight bonding for years.

Another vital process is when removing the PPF when car owner wants to upgrade their drive or change to a new PPF, at this time, a high quality PPF should leave no glue on paint surface. Long-term stability of controlled tack and cohesion to ensure no glue residue-The perfect match of glue and TPU film, can be pasted repeatedly, rework and stretch without leaving glue residue, ensuring the easiest modification and upgrade next time

Warranty

Finally, it is essential to choose a protective film that comes with a warranty. A good warranty should offer at least five years of coverage and should cover any defects or issues with the film.

Choosing the right protective film for your car’s paint can be a challenging task. However, by considering the factors mentioned above, such as thickness, clarity, self-healing properties, ease of installation, and warranty, you can make an informed decision that will keep your car looking like new for years to come.

In conclusion- PPF has been around for a while and the demand is on the increase by the minute, if you are thinking about putting those products to your line, make sure you have a basic understanding of this product and how to tell the differences of the good product. With the above-mentioned info, a good quality paint protection film should be made of the TPU materials, with a thick and durable coating for self-repair, UV protection, and finally the glue that needs to be potent and lasting.

KSB film materials have been in the thin film production for more than a decade and it has gained a good reputation as a reliable film supplier in China. If you are looking for a supplier for paint protection films, please talk to our sales.