When it comes to auto window films, general car users will be confused with so many types of film available on the market- nano ceramic films, nano carbon films, high performance films, dyed films, metallic films and so on. But no matter what names the film comes with, or indicates, the primary function of a window film for vehicle is to block heat, UV, and enhance safety and privacy.

But some window films come with higher clarity than others, or sometimes we see the low-quality window films that is foggy and it blurs the vision.

A premium quality window film should have certain features, such as high clarity, consistent color range, high heat rejection ability, Full UV protections, reliable glue functions, and an easy workability.

So, what makes the window film the clarity and possible causes of low-angle-haze?

To better understand the root causes, let’s first look at -The below picture that illustrates the construction of typical nano ceramic window film. And they are (from top to bottom):

- Wear Resistant Protective Layer

- Polyester Film

- Nano Heat Insulation material

- Polyester Film

- Pressure Sensitive Layer

- UV absorbing Function Layer

- Release liner

Each layer of the auto nano ceramic film will impact the overall clarity of the final window film product. Simply put, high quality materials, with high quality production facility and technics will have a better chance to produce a high-quality product.

1. Low angle haze-Densely packed nano particles clustering and uneven distribution:

A light hazy appearance, known as Low Angle Haze, is a phenomenon that appeared after the window film is installed on windows. It’s caused by the microscopic solid particles of unequal size and arrangement on the ceramic layer of any ceramic film.

Low angle haze may occur to a nano ceramic, carbon ceramic or nano carbon window film, as long as the nano material is applied to improve the heat rejection functionality. When the light is projected at a low angle to the vehicle window, the film may look like blurry or hazy. Films with high heat rejection may tend to have more this low angle haze problem as they requirement more Nano particles to function as a heat blocker. This phenomenon is caused by the microscopic particles’ distribution on the base PET film.

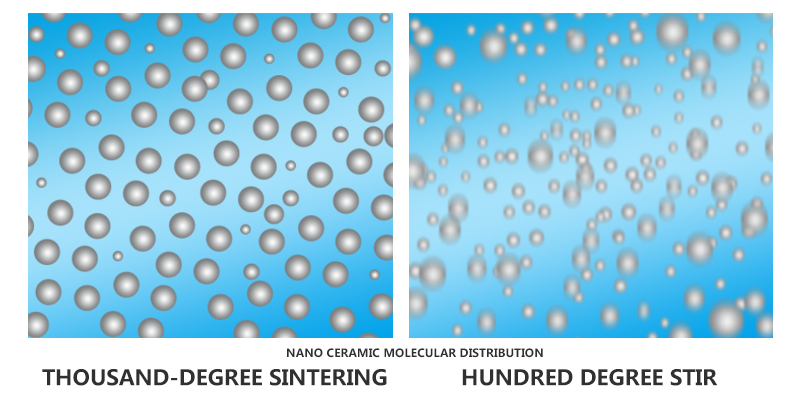

The below photo shows a nano particles distribution compare before two different treatments of the nano materials.

As shown in the above chart, an evenly and symmetrical spacing among the nano particles will greatly reduce the low angle haze and improves the film clarity. On the contrary an unsymmetrical nano particles distribution will make them a cluster and thus lights coming through those clusters will be diffused or redirected at a random angle, making the film looks blurry or haze.

KSB films has developed a proprietary encapsulation process solving this concern. Now, the microscopic carbon or ceramic particles won’t clump, and will remain symmetrical. The end result is the lowest Low Angle Haze of any nano ceramic window films.

Many manufactures are trying to get the IR rejection to 100% by packing their IR films with ceramic particles so densely that IR wavelengths are unable to penetrate them. This will also make the film look hazier if the nano particles are not evenly shaped and coated on the base film.

Nano Ceramic film clarity compare:

One technic is important for the film to have high clarity, besides the quality of the Substrate-The distribution of Nano ceramic molecular structure. There are two ways of the Nano ceramic material Coating-Thousand-degree sintering and hundred degrees stir. The Nano IR absorber comes in as powder, to get them coated on the films. To save cost and time, some manufacturer, stirrer up and mix the heat rejection material with just hot water-this is an inexpensive way, but the disadvantage is obvious, the particles are not evenly coated on the film nor in uniform sizes. When the light comes through, they diffuse light in different angles and this can make the film foggy or distort the view. The Nano-powder itself is in a soft agglomeration state. We need to use wet grinding equipment and processes to separate the soft agglomeration. The Nano powder needs to be processed at 800-1000℃, so that big particles are fine-treated into more evenly uniformed size. A good quality Nano film will have high IR rejection, low reflectivity, and high clarity.

2. PET quality

Besides the Nano particles distribution on the base pet film, the quality of the PET also plays an important role in making a high optical clear film. This is easy to understand. For example, plastic bags, it does not take much to tell difference between a quality bag from an inferior one made of recycled plastics.

A great PET for automotive window tint shall have a high optical clarity and high shrink ability. KSB nano film applies premium high clear PET film from Troy and other well-known suppliers.

3. Glue matters

Glue is another important factor to a high optical clarity film. A high-quality glue should be one with high transparency, strong adhesiveness and removable after certain period of service. High quality glue plays important roles for a window film, not only the transparency or high clarity of it, but also preventing a film to bubble. The volatile compounds in the glue affects the film quality, because film will bubble if the bonding force and volatile compounds is too much in the glue.

4. IR and UV blocker positioning

two important components to mention, the IR absorber and the UV inhibitors to absorb or reflect away heat and the UV ray.

But where are they placed? This makes a huge difference.

One way is to infuse the UV inhibitors with the mounting adhesive, because they are the first layer to get in contact with the sunshine after it penetrates the glass. So, the first PET-closest one to the glass is protected from UV rays and to prevent the color fading or become foggy. But this can be the opposite for exterior window films, for which the UV layer is placed on the Scratch-resistant coating.

A good film should have a high UV cut, so the color becomes more stable, the theory is simple, but UV inhibitors are expensive, some cheap films will apply a fluorescent agent to substitute the UV inhibitors, 1/3 cost

The fluorescent agent does not get along well with the mounting adhesives, not like the UV inhibitors. So, the fluorescent agent is placed between the second PET and the SR coating for a film to be with nearly 100% UV. Ater a certain period of time, the fluorescent agent become blurry and the first layer of PET is not well protected by the UV inhibitors mixed within the mounting adhesive-they begin to look foggy.

When selecting window films with optimal clarity, try compare the film clarity with special instruments to test the window film clarity index. Test install them on windshield and see if there is low angle haze when driving in sunrise or sunset times to the light, see if there is a blurry vision.

If you are looking for high heat rejecting and high clarity ceramic films at competitive prices, KSB films is your choice.