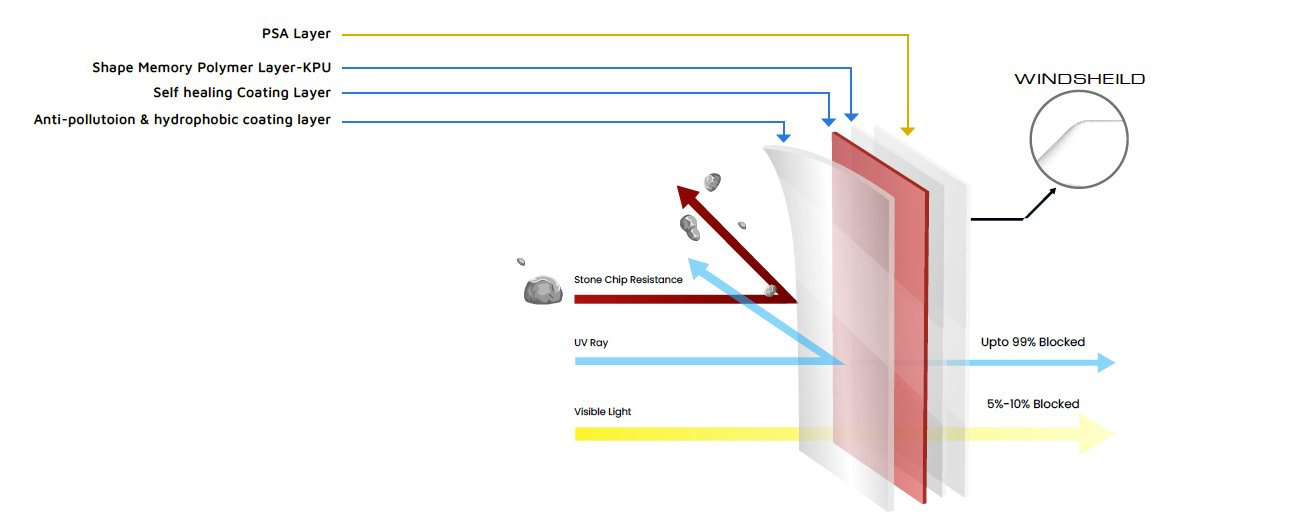

KSB AK85 Exterior Windshield protection film is a transparent, durable film applied to the exterior of a vehicle’s windshield to provide protection against various hazards and damage. This film is made from a clear EPU material that is resistant to scratches, chips, and impact from road debris such as rocks, gravel, and insects.

The primary purpose of windshield protection film is to prevent damage to the windshield and maintain its clarity and visibility. It acts as a sacrificial barrier, absorbing the impact of small objects and preventing them from causing chips, cracks, or other forms of damage to the glass.

In addition to protection against physical damage, KSB AK85 windshield protection films also offer other benefits such as UV protection, heat rejection, and improved aerodynamics. These films can help reduce glare, heat buildup, and interior fading caused by prolonged exposure to sunlight.

7.5 mil thickness

48″ x 50′

1 year’s warranty

Ask us about our total vehicle protection solutions – Auto windshield protection film, paint protection and our wide array of window film product options.

| ITEM | RESULT | MEASUREMENT | REFERENCE |

| Product thickness | 7.5 MIL | μm | Thickness gauge |

| Adhesive strength(gf/inch) | >200 | gf/inch | ASTM D 3330 |

| Scratch restoration | <10 | min | Copper brush(Room temp230C)Higher the temperature the faster surface recovery |

| Water contact angle | 105 | ASTM D5946 | |

| UV resistance % | 99.9 | % | UV METER |

| Transmittance % | >91 | Mpa | CM 3600A KONICA |

| Haze | <0.8 | % | CM 3600A KONICA |

| Stone Chip resistance -Stone | No effected area | – | Gravelometer chip impact testing |

| Stain resistance, Water & soap spotting, acid rain, acidic materials(bird feces, berries) acetone, etc | No effected area | Rest for 40~1hr, check after 24hr | Japan test standard |

Performance results are calculated using Linshang Window Film Measuring Instruments, and are subject to variations within industry standards and only intended for estimating purposes. This data is provided for informational purposes only and are subject to normal manufacturing variances.

Performance results based on film applied to W (6mm) dear glass and a representative automotive glass with a base visible light transmission of 75%. Due to variations in glass performance. these values should not be used to comply with local tinting laws.

[1] VLT stands for Visible Light Transmission, -the percentage of visible light that passes through a window film or tint. It is to indicate how much light is allowed to pass through the film and into the interior of a vehicle or building. A higher VLT percentage means more light is transmitted, resulting in brighter interiors, while a lower VLT percentage means less light is transmitted, resulting in darker interiors.

[2] INFRARED ENERGY REJECTION (IRER) The percent of infrared energy (780 nm to 2500 nm) that is directly reflected and absorbed and radiated outwards. The higher the number, the more infrared energy reflected and absorbed and released outwards. IRER is the endorsed calculation method of IWFA.